What’s a realistic Hydrogen roadmap to 2050?

Author: Gareth Davis, Principal FES Engineer at Costain

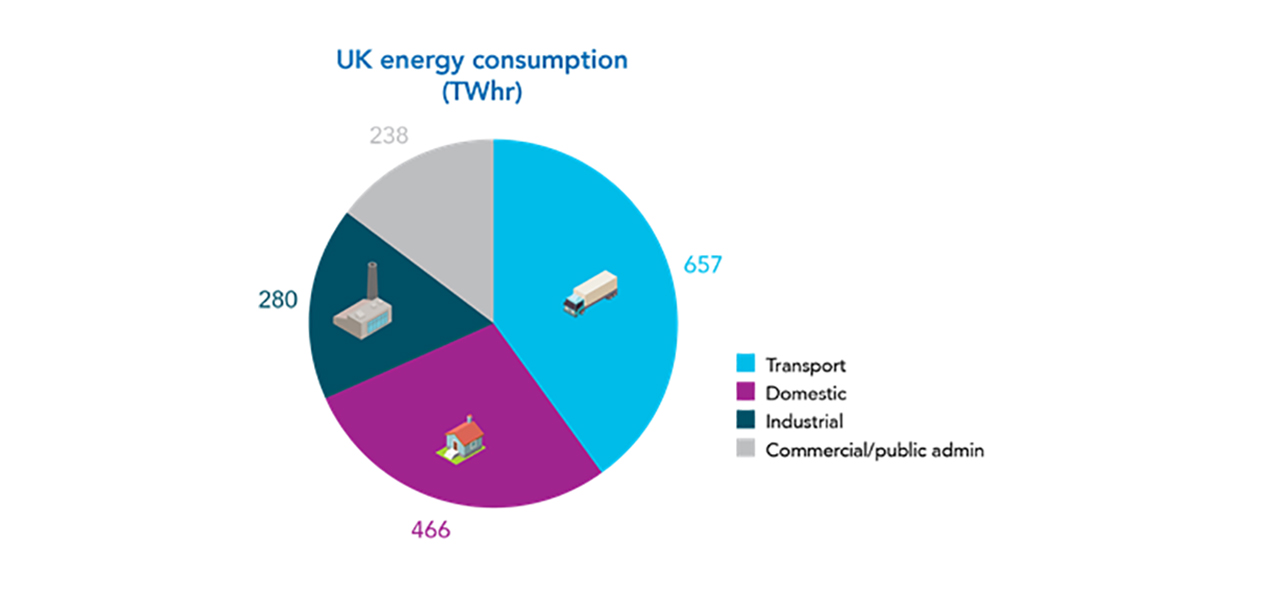

If we were to accept that hydrogen could play a significant role in plugging the energy gap and accelerating the UK’s journey towards net zero carbon by 2050, what would a roadmap for a hydrogen economy look like? Yes, hydrogen would require infrastructure to get it from point of production to the end user and significant capital investment would be needed. However, if we use existing infrastructure with proven industrial technologies to incrementally grow the UK’s capacity and capability to produce hydrogen, the investments can also be incremental, and the associated risks managed more effectively. What’s more, hydrogen offers a number of potential routes to zero carbon energy: it can be applied across a range of sectors and has a variety of applications within those sectors. A hydrogen economy isn’t entirely dependent on adopting hydrogen for all energy uses. As the chart below illustrates, just using hydrogen in either transport, industry, or as a blended fuel in our heating network alone would make significant strides towards decarbonised energy. While hydrogen has its fair share of uncertainties, its potential flexibility in meeting energy requirements for heat and transport is worth exploring. With a keen eye on the deliverability and drawing on 60 years’ experience of developing and delivering energy infrastructure, we’ve been shaping future scenarios and creating some realistic roadmaps. Our first roadmap explores routes to a hydrogen economy in the UK through heating.

A recent study for BEIS2 on fuel switching estimated that hydrogen has the highest technical potential for industrial heat compared to biomass, waste or least likely, electricity. However, decarbonising heat with hydrogen has advantages in both an industrial and domestic setting.

In the domestic setting, there would be limited disruption in switching to hydrogen as conversion of boilers, cookers and other appliances to hydrogen would be straightforward to undertake. Indeed, the UK has the enviable position of having gone through a similar change before in the 1960s and 70s when the country was converted from towns gas (up to 50% hydrogen) to natural gas from the North Sea. Currently, 20% hydrogen (with natural gas) and 100% hydrogen are being evaluated in the UK. Ongoing testing programmes such as the HyDeploy project at Keele University are expected to demonstrate that the vast majority of domestic appliances, such as boilers and cookers, will not require modification to operate with 20% hydrogen.

Based on current understanding, there are big step changes in infrastructure requirements between the case for 20% and 100% hydrogen in the gas grid. Costain’s process engineering know-how from decades in industrial gases and hydrocarbons has enabled us to demonstrate to UK gas network stakeholders how deblending technology can be used to manage the transition between different levels of hydrogen in the network, providing domestic and industrial consumers with the concentration of hydrogen they need.

Deblending makes use of proven technology and would help manage differences in supply and demand as the hydrogen economy develops. Even if a blend of hydrogen is used, it could be separated from the natural gas after being transported (to be covered in a detailed follow up article on deblending). Following conversion to hydrogen, gas would still arrive at a property via the existing distribution system, meaning that customers would experience a smooth transition to decarbonised heat. The added advantage that this is enabled through the development of tried and tested technology would also help consumer confidence. For most consumers, adequate intra-day and inter seasonal storage of hydrogen to manage demand fluctuations would be required. However, industrial users often require high temperatures to be generated which will either be used for direct heating or for indirect heat to generate steam which is then used as a heat transfer medium. Heat for industrial processes is typically a reasonably constant 24-hour demand. The consistency of this requirement, coupled with high energy use at individual sites, makes the possibility of localised or regional hydrogen sub-networks for larger industrial companies a possibility.

The consistency of demand coupled with smaller number of users also makes industrial heat an early target to be switched to hydrogen. The steady demand means there would be no requirement for hydrogen storage, since this could be accommodated by the gas grid itself. This reduces the infrastructure requirements compared to providing hydrogen for domestic heat as well as dealing with a much smaller numbers of consumers.

Production of hydrogen at an industrial scale is well-understood, and already in operation globally, with natural gas being converted to hydrogen at large scale by processes such as Autothermal Reforming (ATR) and Low Carbon Hydrogen (LCH). This produces CO2 as a side-product which is most practically dealt with by carbon capture, usage and storage (CCUS). This is a complex topic and will be the subject of a follow up article, but in summary CCUS is an intrinsic part of industrial scale hydrogen production, whether the storage takes place in geological formations such as depleted oil and gas fields. As part of the UK government clean growth and industrial strategies, five industrial clusters which would include CCUS have been identified. The government goal is to decarbonise one of these by 2040 with an interim low-carbon target by 2030.

The scale of hydrogen production possible with industrial-scale ATR or LCH technology is enormous compared to that achievable by a single electrolysis unit. Developing a single site for industrial-scale production of hydrogen could produce as much as thousands of electrolysis units. As an example, the Hynet NW scheme proposed by Cadent would provide industrial heat to the north west of England by producing 900 MW of hydrogen at a single site. On a large scale, the H21 North of England (NoE) scheme proposes production in nine trains, each with a capacity of 1350 MW making a total of 12,150 MW3. In comparison an electrolysis unit is typically 1 to 5 MW.

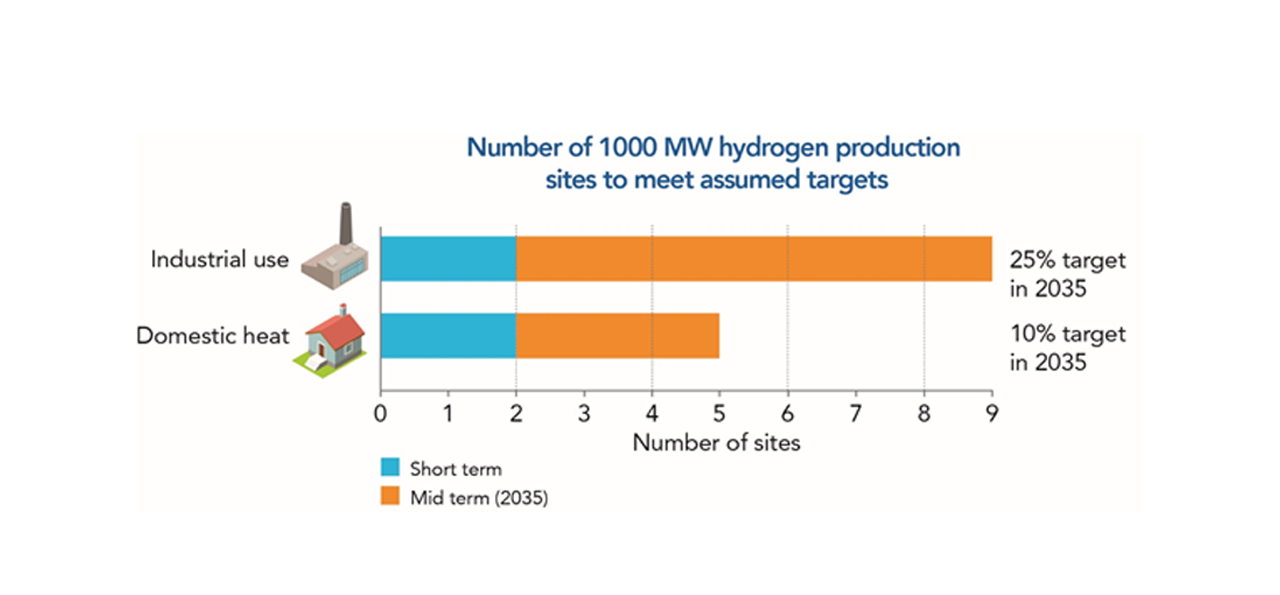

Let’s say development of hydrogen production is targeted to provide 10% of domestic heat and 25% of industrial energy consumption in the UK by 2035. Production is assumed to operate 24 hours a day in conjunction with adequate intra-day and inter-seasonal storage needed for domestic heating. A total of four units based on ATR or LCH technology, each with 1000 MW capacity would be required to meet initial short-term targets of 5% of domestic heat and 10% of industrial energy consumption. A further ten units at this capacity would be required to achieve our assumed 2035 targets.

Larger regional clusters, such as that suggested by H21 NoE, could see hydrogen production concentrated onto just a few sites. The figure below shows the number of 1000 MW hydrogen production sites that would be required to achieve meaningful progress towards the UK government target of net zero carbon by 2050.

The way hydrogen is distributed will reflect the location of production sites, and how potential users are spread geographically. Larger quantities of hydrogen produced by ATR or LCH technology for industrial use would need to be distributed from the production site to users by pipeline, tube trailer (road tanker) or in the longer term, by ship. Distribution of hydrogen for domestic heating using the existing gas grid, either as a blend or as 100% hydrogen has a great advantage, since this makes use of existing infrastructure. A testing programme is already underway to prove the existing gas grid is a safe and efficient way to transport hydrogen.

As Costain’s hydrogen roadmap below illustrates with some interim dates and moderate targets, the short to mid-term industrial production of hydrogen from natural gas using ATR or LCH technology offers a financially, technically and socially viable means of establishing the foundations for a hydrogen economy. In the longer term, we will be able to build on these foundations to realise one of the greenest options which is to use renewable energy to produce hydrogen. The UK has the expertise and existing infrastructure to make significant early progress and accelerating capability and capacity now would put the UK in position to become a key player in this emerging global market. Critical to this will be continued funding from government to the industrial clusters, to enable supply chains to become more established with resulting reduction in costs, as has been seen for other forms of decarbonised energy such as solar and offshore wind.

The building blocks for a hydrogen economy are ready and Costain is working alongside partners and clients to explore their full potential to integrate the broad range of smart infrastructure solutions we will need to shape the UK’s decarbonised energy future.

Keep following us on social media and be first to read our follow up articles which will explore in more detail: Hydrogen and CCUS; deblending hydrogen and as well as hydrogen in transport.

Click here to subscribe to our email alerts and keep up to date with the latest news about Costain and the industry.

The roadmap below gives an overview of the main actions required, and when they are potentially needed, to meet these challenging targets.

Downloads

References

1Energy Consumption in the UK, BEIS, July 2018

2Industrial Fuel Switching Market Engagement Study (for BEIS), Element Energy & Jacobs, Dec 2018

3H21 North of England Report, NGN, Equinor & Cadent, Nov 2018