Delivering decades of operational efficiency and certainty with through-life thinking

Author: Nick Jacques, Principal consultant

Better by design

We live in a world where service delivery is non-negotiable and the safety, resilience, reliability, and security of Critical National Infrastructure (CNI) is paramount. Whether it’s transport networks, supply of energy, water, broadband or a military response to an international crisis, there is expectation that timely service will meet demand without fail.

Now, more than ever, it is essential to integrate a through-life approach to the asset (rather than limiting to a project lifecycle approach) from the start of the design process through to the operation. It’s not just the engineering design of the major asset that is needed to deliver availability but also the ‘operate and maintain’ elements, such as trained personnel, the right infrastructure, efficient processes, data and information, supply chain and logistics and the right type of organisation to deliver it. If these are in place, sustaining availability of major assets in environments where continuous operation is critical is possible. But who is responsible for it and how do you ensure delivery?

It’s a load of hyperbolics!

Despite a common understanding of the need for a through-life approach, decisions are often made during the design and construction of a major asset that adversely impact the availability and efficiency of its future operation. Why?

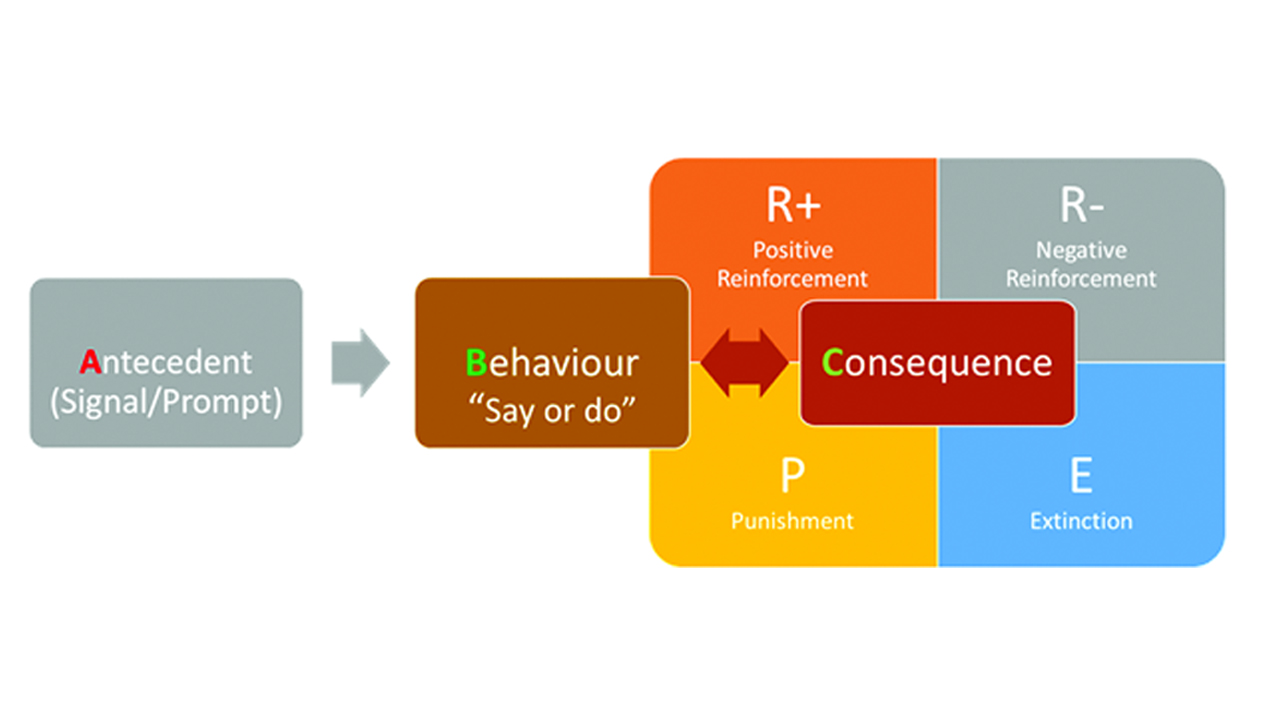

Although we may know the outcomes we desire, our behaviours frequently cause us to make decisions that solve a near term problem whilst generating a bigger one for the future. Behaviour is driven by the consequences of our actions, with the most successful behavioural change occurring when consequence is likely to be reinforced immediately. This is known as hyperbolic discounting, a cognitive bias that creates temporary preferences for small rewards that occur sooner over larger, later ones. Despite operation and maintenance contributing over 75% of the total cost of acquisition, this bias results in operations and maintenance (O&M) requirements being frequently ‘traded out’ when the programme is challenged on cost or schedule.

The consequences from an operational perspective are neither immediate or certain, whereas from a project delivery perspective they are positively reinforced through a bonus or by avoiding punishment for missing targets. This means that decisions taken to reduce costs in the procurement phase can have significant adverse effects on future performance and cost, but any adverse consequences are not felt by the decision maker.

A whole range of factors influence decisions during the acquisition of major assets:

- Lack of involvement from skilled and qualified operations professionals in the design process

- Lag between decisions and impact

- High profile delivery vs unglamorous ongoing support.

However, the separation of capital expenditure (CapEx) and operational expenditure (OpEX) is the biggest issue impacting through-life thinking. Moving toward a combined total expenditure (TotEx) approach would help, however the sums involved in O&M across multiple decades can be eyewatering and unpalatable from a public and political perspective.

‘Making continuous service delivery a ‘now’ requirement’

When an asset is commissioned and transitioned into service, responsibility for delivering output lies with the organisation’s operations management team. However, their ability to meet demands can be constrained by decisions made early in the design process that they might not have been involved in.

During the design and construction phases of a complex project, if you ask someone what they are working on, the answer is typically ‘we are building the latest power station, rail line, submarine’. As strategic advisors working with intelligent clients, it’s our job to help change this mindset. Like the NASA janitor, who was asked by President Kennedy what he did and replied “I’m helping put a man on the moon”, we can align ourselves to the task of providing the capability that the asset will be delivering throughout its operating life.

Even at the very early acquisition stage, every function and department has a part to play in ensuring that the support system will deliver effective, efficient, resilient, safe, sustained, and secure operation of the asset. Costain’s major asset support lifecycle (below) identifies the high-level activities required to ensure that each functions’ processes, controls, and reward structures reinforce desired behaviours.

Major asset support is a team sport. Let’s take a look at the team involved and their responsibilities:

The senior management team – delivering horizontal integration to drive efficiency

- Defining the O&M strategy in line with business constraints and considering how this works across all assets

- Determining the one key driver of through life activity – forecasted demand

- Exhibiting and reinforcing desired behaviours.

Project managers - ensuring the project management plan includes support requirements

- Checking the resource plan demands the appropriate capacity and capability of operations personnel to develop the solution

- Putting in place a transition to service plan, back scheduled from handover date.

Project controls – guardians of consequences

- Ensuring O&M requirements are reflected in project metrics and are a mix of lead and lag indicators

- Managing the change process so impacts on O&M are minimised

- Assessing risks associated with the change ensuring that its maintained in the project risk register and carried over into operating environment.

Design engineers – design for continuous service delivery

- Designing for availability through building in redundancy, standardised modular components and utilising remote diagnostics and fix, using a common information backbone

- Ensuring design minimises any operating costs by considering elements such as energy costs, numbers and skills of the staff

- Considering obsolescence through operational life.

Commercial staff – aligning contracts with O&M strategy

- Ensuring clarity around accountability and responsibility between suppliers and the suppliers and the client

- Driving desired behaviour through the construct of the contract.

Operations need to ensure that they own the requirements for all essential elements when the asset is handed over and enters service. This approach is supported by PAS 280; Through-Life Engineering Services which outlines the activities and capabilities necessary to maximise value for all stakeholders over a major asset's lifecycle. The standard does maintain the balance required between engineering and business planning to ensure delivery of world class performance.

The right consequences to get the right result

So, is your organisation set up to deliver efficiency and an optimised outcome, or are problems left to the future for someone else to deal with? Is it possible to embed consequences that help deliver the desired result? Would structuring your processes, metrics and reward mechanisms in a way that positively reinforces the right behaviour, make the consequences immediate and likely? It will at least ensure that decisions are consciously made with long-term operational impact and risks identified and importantly, transparent. It is critical that all involved in delivering the asset understand that their role is to deliver decades of operational capability not just handover a nice new shiny, high-profile asset. This way decisions will be properly scrutinised and issues won’t become somebody else’s problem in the future.