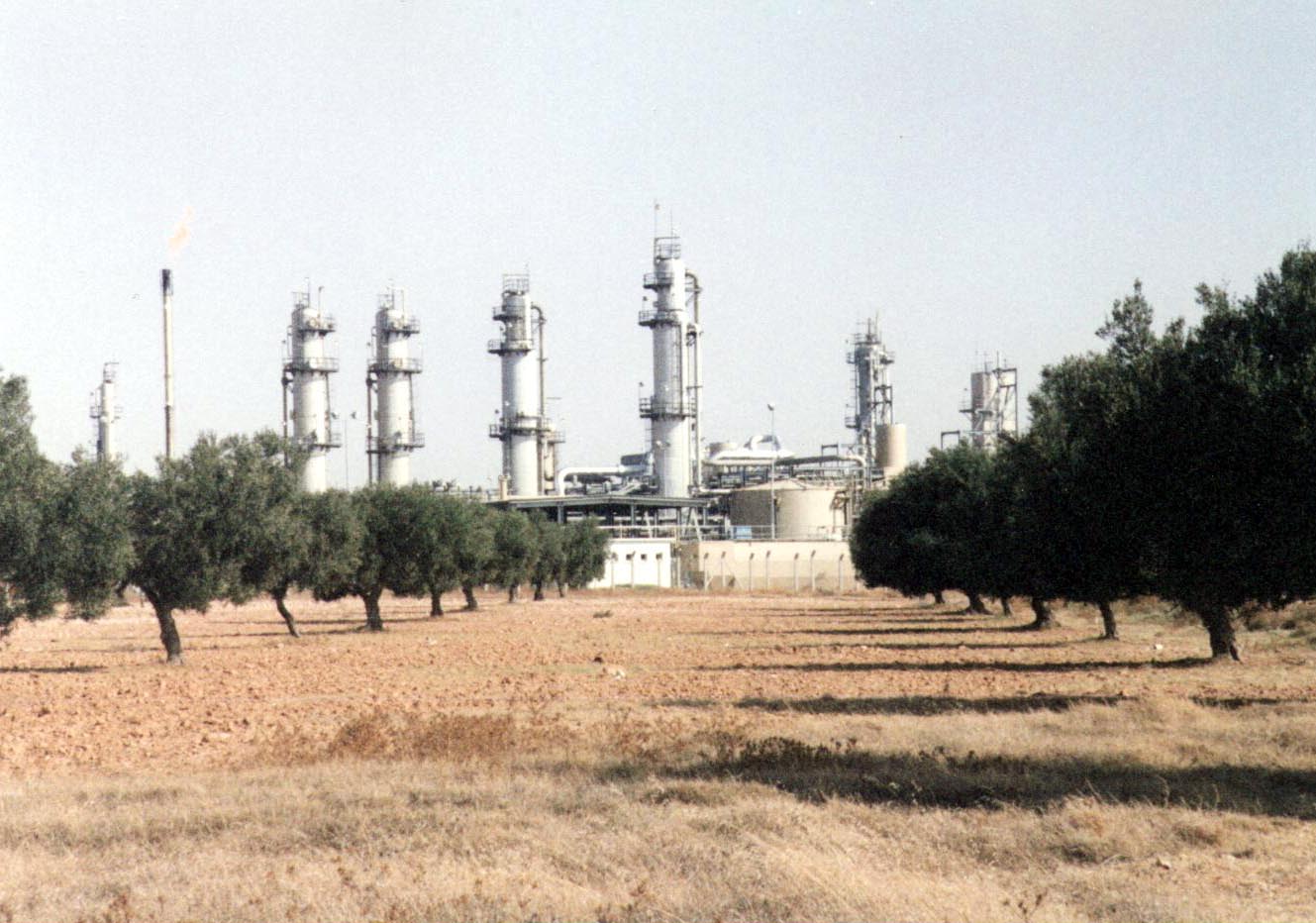

Delivering Long Term Nitrogen Rejection Solutions for Tunisia's Gas

Costain consultants were engaged by BG Tunisia to provide engineering expertise in de-bottlenecking of the NRU. The NRU, which was originally supplied by Costain, was required to reduce nitrogen from almost 20% to 6.5%.

- Service 1

- Service 1

BG Tunisia

- Service 1

- Service 1

- Service 1

- Service 1

Advisory and Concept Development

Specialist Design

Technology Integration

Asset Optimisation

Challenges

Cost reduction

Minimum CAPEX and OPEX were required

High degree of reliability and availability

for efficient operation

Nitrogen content reduced to 6.5%

to meet sales gas specification

Designed to minimize downtime

during the later construction phase

Costain carried out the conceptual study and FEED for the project and achieved the design challenges by:

- Using proprietary cryogenic technology to process natural gas containing 55% nitrogen with Joule-Thompson refrigeration and separation

- Upgrading the reboiler circuit to provide a forced recirculation to overcome deficiencies in the original thermosyphon reboiler design

- Specifying improved reboiler return column distribution

- Making design decisions which ensured that a modular approach could be implemented to simplify construction

The cost effective design and leading engineering expertise demonstrated during concept and FEED resulted in the following:

- A 10% increase in sales gas capacity to 200 MMSCFD was achieved

- Costain selected to carry out detailed design, construction and commissioning

- Cost certainty and flexible decision making for the client, resulting in project delivery ahead of time and under budget.

Costain provided a solution which gave high levels of reliability and availability while keeping the process simple. This resulted in substantial commercial cost savings for the client. The Costain solution offered the flexibility and reliability to export gas either to the NTS or to the adjacent gas fired power station, allowing the customer to maximise asset profitability.

As well as nitrogen rejection, the following was provided:

- H2S and total sulphur removal

- Dehydration

- Compression

- Odorising